Fleet vehicles, from delivery vans to service trucks, rely on a vast network of electrical systems to keep their operations running smoothly. The wiring harness is the backbone of these systems, connecting all essential components, such as lights, sensors, and engines, to the vehicle’s power source. As with any critical system, ensuring the wiring harness is in good health is vital to avoid unexpected breakdowns and maximize vehicle uptime. Regular wiring harness inspections can significantly reduce the risk of failures that might otherwise disrupt fleet operations.

The Impact of Wiring Issues on Fleet Productivity

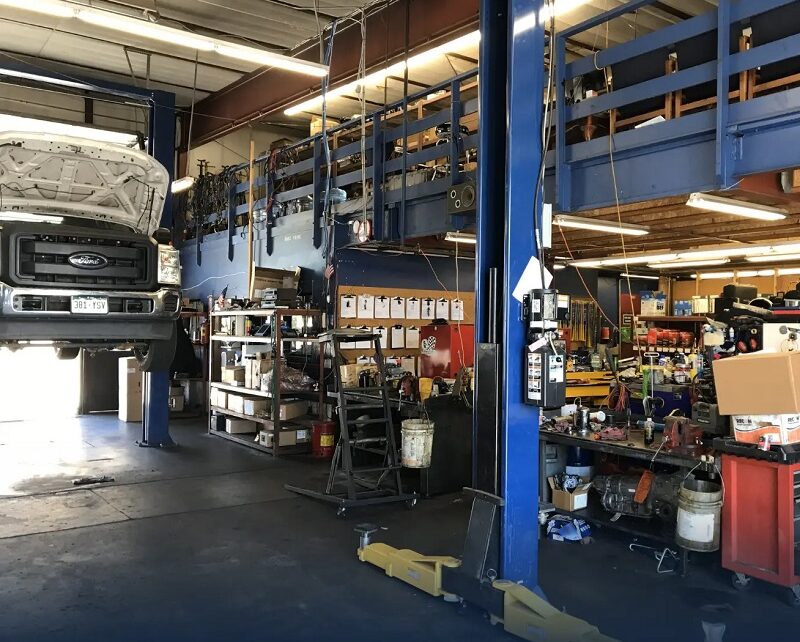

Wiring issues, whether from wear and tear, road vibrations, or environmental factors, can lead to frustrating electrical malfunctions, such as faulty lights, non-functional power windows, or unreliable sensors. In a fleet setting, these problems can lead to delays, unscheduled repairs, and costly downtime. Malfunctioning wiring can also trigger error codes that may cause the vehicle to enter limp mode or even shut down entirely, leaving your driver stranded and costing valuable time and resources. Proactive inspections help prevent these issues, keeping vehicles on the road and minimizing interruptions. Selection of the European Auto Repair in Middle River, MD based services is essential here.

Preventing Unnecessary Repairs and Costs

Electrical system issues can be notoriously difficult to diagnose, and wiring harness problems are no exception. Without regular inspections, seemingly small issues—like loose connections or minor corrosion—can develop into more significant problems, resulting in expensive repairs or even the need for a complete harness replacement. Routine checks allow fleet managers to identify potential faults early, addressing them before they cause major damage. This not only saves money but also ensures that the vehicles are operating at peak performance, preventing costly repair delays.

Avoiding Safety Hazards

Fleet vehicles, particularly those used for public service or deliveries, are subject to strict safety regulations. A faulty wiring harness can compromise critical safety features, such as brake lights, turn signals, or even airbags. In some cases, damaged wiring may lead to erratic behavior in driver-assistance systems, such as lane departure warnings or collision sensors. Regular inspections of the wiring harness help ensure that safety systems remain fully operational and compliant with regulations, preventing potential accidents and ensuring the safety of both drivers and pedestrians.

Extending Vehicle Lifespan

Fleet vehicles undergo heavy use, and their wiring systems are subjected to constant stress. Over time, environmental factors like extreme temperatures, humidity, and road debris can degrade the wiring harness. By conducting regular inspections, fleet managers can catch wear and tear before it becomes a serious issue. This helps extend the lifespan of the vehicle, allowing the fleet to operate more efficiently and reduce the need for premature replacements. Regular maintenance ensures that the fleet runs smoothly for as long as possible, providing better returns on investment.

In conclusion, regular wiring harness inspections are essential for fleet vehicles to maintain operational efficiency, safety, and cost-effectiveness. By catching problems early, fleet managers can minimize downtime, prevent major repairs, and ensure their vehicles stay on the road longer, ultimately contributing to a more reliable and productive fleet.